| Line 14: | Line 14: | ||

* apply the validated numerical framework to identify the key contributing parameters to fouling mechanisms and its mitigation in porous metal foams in turbulent heated flows. | * apply the validated numerical framework to identify the key contributing parameters to fouling mechanisms and its mitigation in porous metal foams in turbulent heated flows. | ||

| − | <-- === Foam Image === | + | <-- === Foam Image ===--|> |

| − | {| class="wikitable" | + | <--{| class="wikitable"--|> |

| − | |[[File:Specimen.png|400 px]] | + | <--|[[File:Specimen.png|400 px]]--|> |

| − | |} | + | <--|}--|> |

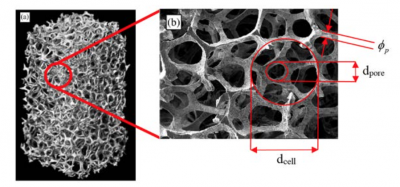

| − | (a) Aluminium foam specimen image obtained via X ray computed microtomography [1] (b) magnified image of the specimen with d_cell ≈ 2.25 mm [2], d_pore ≈ 1 mm and φ_p ~ 0.25-0.45 mm | + | <--(a) Aluminium foam specimen image obtained via X ray computed microtomography [1] (b) magnified image of the specimen with d_cell ≈ 2.25 mm [2], d_pore ≈ 1 mm and φ_p ~ 0.25-0.45 mm--|> |

| − | --|> | + | |

| + | |||

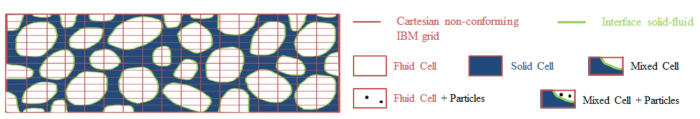

| + | === An IBM strategy === | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | |||

|[[File:OUIIBM.png|700 px]] | |[[File:OUIIBM.png|700 px]] | ||

|} | |} | ||

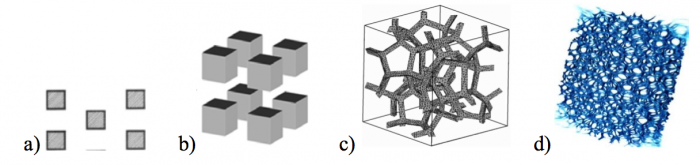

| + | === Idealized and realistic geometries === | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | | | + | | |

|[[File:OUIGeometries.png|700 px]] | |[[File:OUIGeometries.png|700 px]] | ||

|} | |} | ||

| Line 38: | Line 40: | ||

| − | 1. Ranut, P., E. Nobile, and L. Mancini, Applied Thermal Engineering, 2014. 69(1-2): p. 230-240. | + | <--1. Ranut, P., E. Nobile, and L. Mancini, Applied Thermal Engineering, 2014. 69(1-2): p. 230-240. --|> |

| − | 2. Dyga, R. and M. Placzek, Experimental thermal and fluid science, 2015. 65: p. 1-12. | + | <--2. Dyga, R. and M. Placzek, Experimental thermal and fluid science, 2015. 65: p. 1-12. --|> |

== Participants == | == Participants == | ||

Emilie Sauret, Sofiane Khelladi, Thomas Sarfati, Lucas Manueco, Eric Herbert, Yves D'Angelo. | Emilie Sauret, Sofiane Khelladi, Thomas Sarfati, Lucas Manueco, Eric Herbert, Yves D'Angelo. | ||

Revision as of 15:33, 1 April 2016

Contents

Flow, heat transfer & particle transport in metal foams

Context

Porous media are nowadays common materials in many thermal or mechanical engineering applications such as heat exchangers or oil/air separators [Ce2007]. However, since a few decades, a new type of such "macro- porous" media called metal foams often used in the engineering field has emerged. Compared to other standard materials, metal foams or metfoams constitute a new class of materials, known to have many interesting combinations of physical & mechanical properties.

Target Applications, Hurdles

Since the possible fields of applications of metal foams are very large, this project has the ambition to tackle the challenge of proposing a numerical/experimental methodology in order to create the design tools for next generation metal foams conception & optimization, by not only characterizing but also proposing & determining the more adapted macro/micro scale pore structure for each specific application. We shall mainly focus on developing a methodology for the design of high performance compact heat exchangers and heat sinks, e.g. in the context of the thermal management of direct thermo-electric converters or electronic devices coolers, for instance in the context of LED thermal management. Above the enhanced thermal conduction or the desired filtering, undesired particulate fouling is a common phenomenon in porous media/metal foams and may dramatically reduce the heat transfer efficiency.

Main objectives

The main research objectives are to:

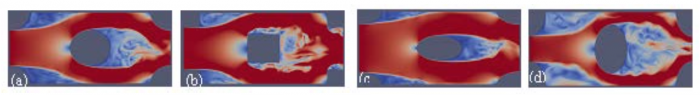

- develop a numerical framework based on an Immersed Boundary Method (IBM) including a Level-Set technique for tracking the complex fluid/solid interface,

- incorporate for the first time all physical interactions between turbulent flow, particles and heat transfer in complex porous structures within the proposed framework while preserving high-order accuracy,

- enable systematic model validation through new pore-scale experiments on idealized and real foams for improved understanding of particulate fouling mechanisms in complex turbulent flows subject to heat transfer, and

- apply the validated numerical framework to identify the key contributing parameters to fouling mechanisms and its mitigation in porous metal foams in turbulent heated flows.

<-- === Foam Image ===--|>

<--{| class="wikitable"--|>

<--| --|>

<--|}--|>

<--(a) Aluminium foam specimen image obtained via X ray computed microtomography [1] (b) magnified image of the specimen with d_cell ≈ 2.25 mm [2], d_pore ≈ 1 mm and φ_p ~ 0.25-0.45 mm--|>

--|>

<--|}--|>

<--(a) Aluminium foam specimen image obtained via X ray computed microtomography [1] (b) magnified image of the specimen with d_cell ≈ 2.25 mm [2], d_pore ≈ 1 mm and φ_p ~ 0.25-0.45 mm--|>

An IBM strategy

|

Idealized and realistic geometries

|

|

<--1. Ranut, P., E. Nobile, and L. Mancini, Applied Thermal Engineering, 2014. 69(1-2): p. 230-240. --|>

<--2. Dyga, R. and M. Placzek, Experimental thermal and fluid science, 2015. 65: p. 1-12. --|>

Participants

Emilie Sauret, Sofiane Khelladi, Thomas Sarfati, Lucas Manueco, Eric Herbert, Yves D'Angelo.